04 Jun OTC In-Wall Humidity Detection – One Way We’re Using Big Data to Help Our Clients Prevent Costly Mold Issues

Mold. When it comes to building maintenance, it’s the one word that no one wants to hear. Mold remediation, particularly in-wall mold remediation, can be an incredibly expensive and time-consuming undertaking, and up until now, there has been little we could do to detect and fix hidden moisture problems before they became costly mold issues. But that is changing, and IoEnergy is leading the charge by collaborating with one of our control partners, Monnit, on the development of in-wall humidity detection sensors. These sensors have the potential to detect the conditions that make mold possible and fix them before it takes a foothold. Conversely, their data-gathering capabilities can help building owners defend themselves against expensive hidden mold claims, because they can deliver proof of a dry in-wall environment, if that is the case.

NEXT GEN WIRELESS HUMIDITY DETECTION GOES WHERE NO SENSOR HAS GONE BEFORE

For years we have benefitted from wireless humidity detection appropriate for interior- and crawl-spaces, ducts and exterior walls, but wireless measurement of in-wall humidity had no over-the-counter solution. Through our work with Monnit, we have developed exactly that – and we are currently testing its efficacy on behalf of the building owner at the Texas Department of Human Services – Copperas Cove site.

We installed Monnits’s ALTA Wireless and Humidity sensor to measure the in-wall humidity at the Copperas Cove site. The sensors were installed right below two selected windows, as leaky windows are one of the most common causes of mold issues. We placed the sensor in a small hole drilled into the wall, and then covered it with protective housing. The sensor collects humidity data from inside the wall, between the studs. The goal is to monitor and identify any high levels of humidity inside the wall in order to alert management to potential issues before mold takes a foothold. The sensor sends data and alerts to a dashboard where abnormalities can be flagged and tracked.

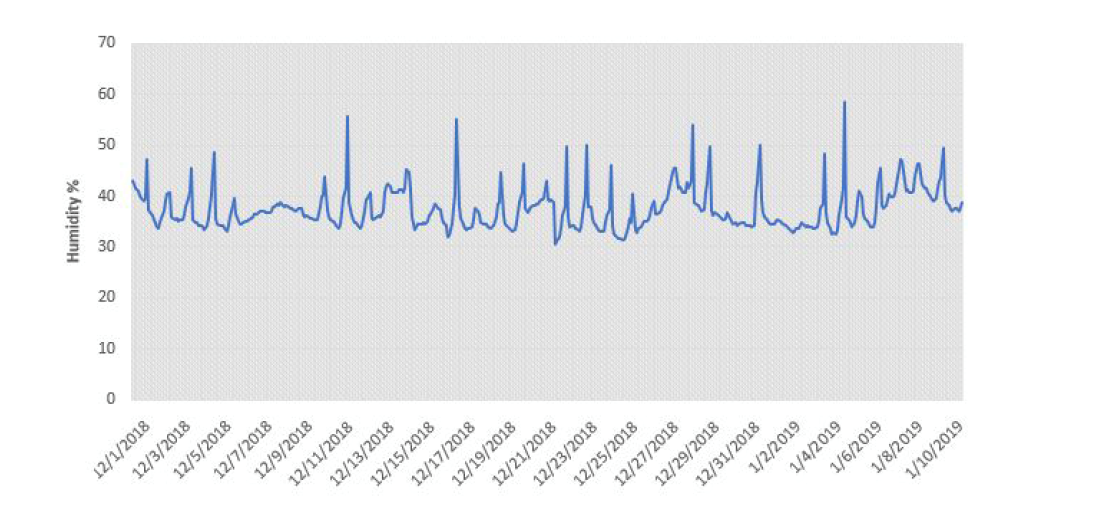

The graph above represents data collected from one of the sensors installed at the Copperas Cove site. The humidity in the graph is within the normal range. The sensor has been collecting humidity data from the day it was installed, and the historical data is being saved in the cloud.

CURRENT TECHNOLOGY LIMITATIONS

While this technology is a useful step in the evolution of in-wall humidity detection, we are still innovating and problem solving to make this detection ever better. The current sensor system will monitor and alert for high humidity level within the stud cavity around windows, but if the leak is located somewhere else in the wall, perhaps as near as twelve feet from the sensor head, it may be difficult to detect. Leaky windows are one of the common causes of mold, but leaks can be found anywhere in the walls besides windows. We are continually studying the results and setting up trials to ascertain the most advantageous sensor placement and level of data granularity required for optimal monitoring.